wood-based

Material

GCC

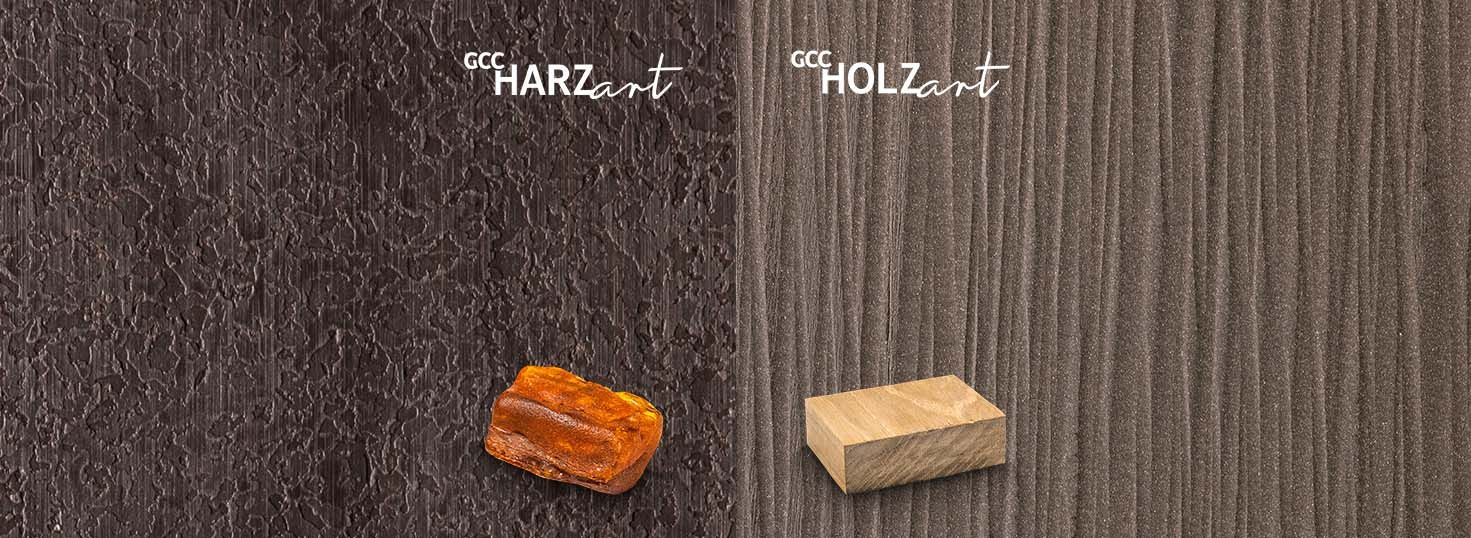

A unique material,

two characters

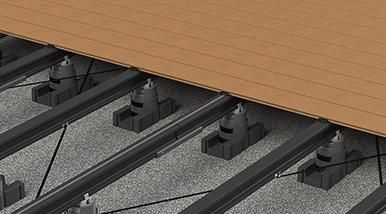

From the raw material to the product in just one manufacturing process:

At our site in Aschersleben, we have the largest and most modern production capacities for the extrusion of wood-polymer materials in Europe. In a patented production process, we mix a high proportion of natural fibres

with the other ingredients of the composition and press the hot mixture

under high pressure through extrusion dies.

GCC (German Compact Composite) is a wood-based material that contains

up to 75% natural fibres in the basic recipe when absolutely dry – a high percentage that is unrivalled worldwide. The wood fibre is therefore the heart of the material! This is supplemented by high-performance polymers made of recycled plastic from first-use industrial applications. Our principle: In addition to wood, we only use as many additives as absolutely necessary and ensure that each of them contributes to the material’s health and recyclability. In some of our products, we replace part of the material recipe with recycled synthetic resin, which enables us to achieve very special, specific product properties.

At our site in Aschersleben, we have the largest and most modern production capacities for the extrusion of wood-polymer materials in Europe. In a patented production process, we mix a high proportion of natural fibres

with the other ingredients of the composition and press the hot mixture

under high pressure through extrusion dies.

GCC (German Compact Composite) is a wood-based material that contains

up to 75% natural fibres in the basic recipe when absolutely dry – a high percentage that is unrivalled worldwide. The wood fibre is therefore the heart of the material! This is supplemented by high-performance polymers made of recycled plastic from first-use industrial applications. Our principle: In addition to wood, we only use as many additives as absolutely necessary and ensure that each of them contributes to the material’s health and recyclability. In some of our products, we replace part of the material recipe with recycled synthetic resin, which enables us to achieve very special, specific product properties.

Our wood-polymer material consists of up to 75% wood fibres. When dry, the fibres are shredded and mixed with polymers with polymers (recycled plastic) and additives (binders and colours). The polymers used serve as “glue” and hold the natural fibres together.

Compared to GCC HOLZart, GCC HARZart replaces some of the ingredients with recycled

synthetic resin. This results in a wood content

of at least 50%. The remaining 50% consists of

the synthetic resin, the polymers, and the

additives. The synthetic resin content lends

the material its name.

The responsible use of resources is part of our philosophy.

For the production of our GCC material, we only use wood fibres that are left over from the planing and sawing industry. The wood for this comes from sustainably managed and PEFC-certified European forest stands - we attach great importance to this. Usually, the wood fibres declared as a waste product are burnt. The carbon bound in it is released into the atmosphere as CO2. Instead, we use the chips as the basis for our products and ensure the permanent storage of carbon in our material by reusing it in the material cycle.

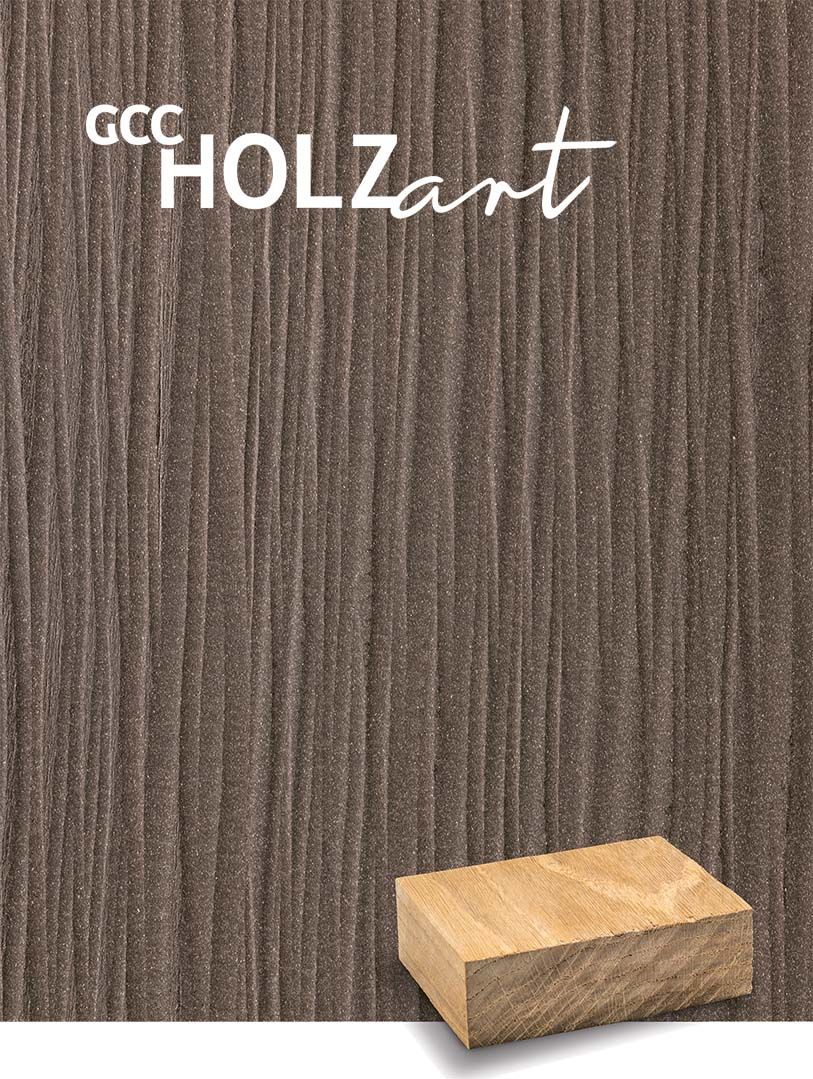

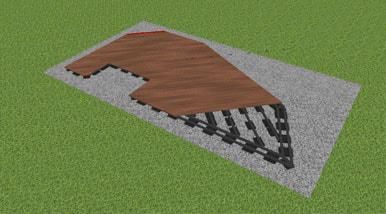

The well-known wood-like character with a wood content of up to 75%.

Wood is good and we make it even better. GCC

HOLZart has all the good properties of the natural

material, radiates just as much heat, and can be

processed in exactly the same way. Due to the

added polymers and the patented extrusion process,

the original softwood is turned into a solid, more

durable wood-based material that withstands the

high mechanical demands of outdoor use and forms

the basis for sustainable construction that spans

generations.

- Contains up to 75 % wood fibres from sustainably managed forests

- Smells and feels like wood

- Planed and brushed surface

- harder and heavier than hardwood

- Stores heat better than wood, heats up significantly less than natural stone, concrete or ceramics

Climate positive - we use what is already there.

An additional source of raw materials for some of our products is recycled synthetic resin, which comes, among other things, from discarded wind power rotor blades. We are pioneers in this field and so far the only company that offers the wind and energy industry a way to recycle old rotor blades.

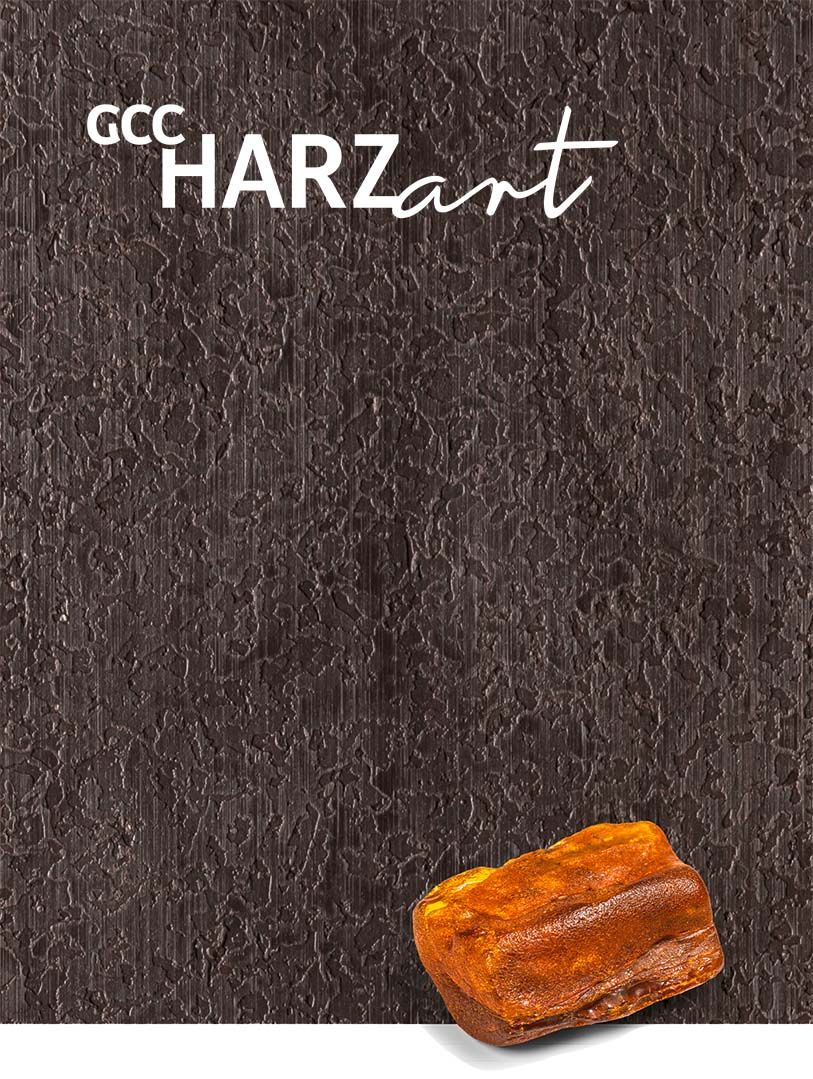

A new amber-loke character with a wood content of over 50% and up to 30% recycled synthetic resin.

GCC HARZart and amber have two things in

common: the feel and the resin. While the tree

resin in amber provides it with its specific properties,

GCC is enriched using synthetic resin.

We obtain it from recycled wind power rotor

blades among other things. In combination with

our unique manufacturing process, this creates

a very special material that can be used in a

variety of outdoor applications. By recycling

raw material components in rotor blades,

we save valuable resources from thermal

destruction or downcycling into inferior

products.

- contains at least 50 % wood fibres from sustainably managed forests

- Addition of up to 30 % recycled synthetic resin

- Feels like amber

- embossed and matt surface

- harder and heavier than hardwood

- Stores heat better than wood, heats up significantly less than natural stone, concrete or ceramics

It's the workmanship that counts.

The impressive wood fibre content of up to 75 % makes our robust GCC HOLZart material just as workable as hardwood. Whether sawing, drilling, sanding or planing - you can bring the consistently homogeneous material into the desired shape using standard woodworking tools.

GCC HARZart has specific properties because it contains synthetic resins from recycled wind power rotor blades for example. It is denser and harder, which leads to greater wear on the tools. The consistently homogeneous material can be bevelled all around. However, we do not recommend full-surface machining operations such as planing,

brushing, or grinding.

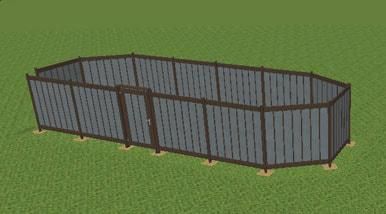

Facade system

Facade system

Time travel – from dinosaurs to the cycle of life

Time travel – from dinosaurs to the cycle of life

Product Safety

Product Safety